- 29mm ribs provide excellent spanning and water-carrying capacity

- Compatible Stramit Monolap® lap joint system allows for single plane, long run roofs

- Suitable for 2 degree minimum roof pitch

Base Material Thickness (mm): 0.42, 0.48

Finish: COLORBOND®, ZINCALUME®

Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Standard Steel Ultra Steel Ultra Steel Ultra Steel Ultra Steel Ultra Steel Ultra Steel SuperDura™ Stainless Steel SuperDura™ Stainless Steel SuperDura™ Stainless Steel SuperDura™ Stainless Steel Metallic Steel Metallic Steel Metallic Steel Metallic Steel Metallic Steel Matt Steel Matt Steel Matt Steel Matt Steel Matt Steel Matt Steel MagnaFlow® MagnaFlow® MagnaFlow® MagnaFlow® MagnaFlow® Other Finishes

COLORBOND® Woodland Grey®

COLORBOND® steel Bluegum®

COLORBOND® steel Dover White™

COLORBOND® steel Southerly®

COLORBOND® Jasper®

COLORBOND® Shale Grey™

COLORBOND® Night Sky®

COLORBOND® Deep Ocean®

COLORBOND® Cottage Green®

COLORBOND® Ironstone®

COLORBOND® Monument®

COLORBOND® Classic Cream™

COLORBOND® Basalt®

COLORBOND® Manor Red®

COLORBOND® Wallaby®

COLORBOND® Gully™

COLORBOND® Pale Eucalypt®

COLORBOND® Windspray®

COLORBOND® Dune®

COLORBOND® Evening Haze®

COLORBOND® Paperbark®

COLORBOND® Surfmist®

COLORBOND® Dune® Ultra

COLORBOND® Monument® Ultra

COLORBOND® Surfmist® Ultra

COLORBOND® Woodland Grey® Ultra

COLORBOND® Wallaby® Ultra

COLORBOND® Windspray® Ultra

Deep Ocean®

Dune

Surfmist®

Windspray®

COLORBOND® Galactic™

COLORBOND® Cosmic™

COLORBOND® Rhea™

COLORBOND® Astro™

COLORBOND® Aries™

COLORBOND® Basalt® Matt

COLORBOND® Monument® Matt

COLORBOND® Surfmist® Matt

COLORBOND® Dune® Matt

COLORBOND® Shale Grey™ Matt

COLORBOND® steel Bluegum®

Off White

Armour Grey

Birch

Monolith

Slate Grey

ZINCALUME®

Certain colour options and finishes may be subject to availability and lead times may vary from site to site. Please contact your local Stramit office to confirm.

Where to Buy

Stramit account holders can buy Stramit Monoclad® Roof and Wall Cladding from their local Stramit office. We do not sell direct to the public but our products are stocked by retail outlets across Australia.

Availability

This product is available Australia-wide. Lead times may vary depending on your location.

News and Case Studies

Check out Stramit’s latest news, product releases and updates, and case studies featuring our quality Aussie-made steel products.

General Information

Stramit Monoclad® Roof and Wall Cladding gives excellent durability in almost all locations. However, it is important to choose the correct coating for each application environment as shown in the table below. Durability recommendations do vary based on the application of the product in roofing or walling installations. Please read these tables carefully.

*>2kn residential buildings

The approximate site exposure conditions in the table above are defined below.

The suitability and exposure tables above are current at time of publication, subject to change, and are guidelines only; conditions will vary from site to site. Please check the Bluescope Technical Bulletins for the latest information and guidance on selection, maintenance and durability. If uncertain about the appropriate coating for a particular application, or if the product is to be used in environments affected by industrial emissions, fossil fuel combustion, animal farming, or has unwashed areas, please contact your nearest Stramit office for advice.

All building products need to be checked for compatibility with adjacent materials. These checks need to be for both direct contact between materials, and where water runs from one material to another.

The following guidelines generally avoid material incompatibility:

- For zinc-aluminium alloy coated steel, colour coated steel and galvanised steel cladding avoid copper, lead, green or treated timber, stainless steel and mortar or concrete.

- Galvanised steel sheets should not receive drainage from aluminium or any inert materials, such as plastics, glass, glazed tiles, colour coated and zinc-aluminium alloy.

Stramit's roofing and walling products should be handled with care at all times to preserve the product capabilities and quality of the finish.

Packs should always be kept dry and stored above ground level while on site. If the products become wet, they should be separated, wiped and placed in the open to promote drying.

Stramit products conform to the following Australian standards that are called up in the NCC.

Steel material

- All metallic coated steel complies with AS 1397

- Painted steel product conforms with AS 2728

Roofing / Walling products

- Roofing/walling profiles conform with AS 1562.1, and AS 4040 parts 0, 1, 2 and 3.

- Corrugated roofing conforms with AS 1445

- Wind Load data conforms to AS 1170 part 2, and/or AS 4055

- Fasteners conform with AS 3566

- Installation details are in accordance with the Standards Australia Handbook HB39

Stramit's roofing and walling products are protected in Australia by registered designs.

All Stramit roofing and wall cladding products conform with, or are equivalent to, AS1562.1.

Stramit has in-house, purpose built testing equipment used to design, develop and improve products for the Australian market. Many of our products are tested or witnessed by independent organisations. These include:

- University of Technology, Sydney

- Cyclone Testing Station (James Cook University)

- The University of Sydney, and

- CSIRO.

The ongoing research and development activity ensure we remain at the forefront of innovation, design and consumer information.

Technical Information

Please refer to the Stramit Roof and Wall Flashing Architectural Detailing Design Guide.

The roofing/walling shall be 0.42 (or 0.48) mm BMT Stramit Monoclad® Roof and Wall Cladding in continuous lengths with trapezoidal ribs approximately 29mm high, spaced at 190mm centres. Sheeting material shall be protected steel sheet to Australian Standard AS1397, with a minimum yield stress of 550MPa (Grade G550) and an AM100/AZ150 coating with an oven-baked paint film of selected colour, or a plain AM125/AZ150 coating.

The sheeting shall be fixed to the purlins/girts in accordance with the manufacturer's recommendations. Suitable fixing screws in accordance with Australian Standards AS3566, Class 3, shall be used at every rib at every support with side lap fasteners installed at mid span if required. Sheets shall be laid in such a manner that the approved side lap faces away from the prevailing weather. A minimum of 50mm shall be provided for projection into gutters. Flashings shall be supplied in compatible materials as specified; minimum cover of flashing shall be 150mm.

All sheeting shall be fixed in a workman-like manner, leaving the job clean and weathertight. Repair minor blemishes with touch-up paint supplied by the roof manufacturer. All debris (nuts, screws, cuttings, filings etc.) shall be cleaned off daily.

Class 4 fasteners should be used <1km from the coast.

A NATSPEC work section is available for this product. Download

Cyclonic Data for Stramit Monoclad® Roof and Wall Cladding can be found in the Stramit Cyclonic Areas Guide.

Information on the use of Stramit Monoclad® Roof and Wall Cladding Roof Cladding can be found in deemed-to-comply sheets No’s M/148/01, M/103/03 and M/104/04. These are available from Stramit or on the NT BAC website.

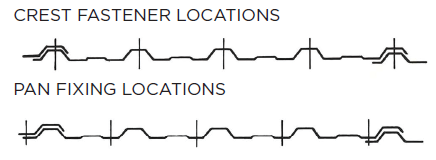

Stramit Monoclad® Roof and Wall Cladding can be fixed with 4 fasteners per sheet at each batten / purlin to meet the required performance values.

All fastening screws must conform to AS3566 - Class 3. They are to be hexagon headed and for roofing must be used with sealing washers.

For connecting to purlins or top hats use:

*For steel less than 1.5mm bmt thickness refer to Stramit® Top Hats & Battens Product Technical Manual.

Foot traffic limits for Stramit Monoclad® Roof and Wall Cladding are shown for 3 alternative foot traffic categories:

Heavy - for applications with repeated maintenance, particularly where personnel may be unfamiliar with correct procedures for walking on metal roofs.

Normal - based on traditional expectations, with moderate maintenance foot traffic using designated foot paths.

Controlled - spans that conform to AS 1562.1:2018 with 1.1kN load as specified in AS/NZS 1170.1:2002 for R2 - Other Roofs. These require minimal careful foot traffic only on the designated footpath. Suggested for use only where occasional aesthetic imperfections from foot traffic are acceptable.

Tables are based on tests to AS 1562.1:2018 and AS 4040 parts 0 and 1.

For more information on foot traffic performance of Stramit's roofing profiles refer to Stramit's Foot Traffic Guide.

Stramit Monoclad® Roof and Wall Cladding is manufactured from hi-tensile G550 colour coated steel, aluminium-zinc-magnesium or zinc-aluminium alloy coated steel. In some locations galvanised and severe environment colour coated steel may be available by arrangement.

Colour coated steels are in accordance with AS/NZS 2728:2013 - Type 4 and, for the substrate, with AS 1397:2021. Aluminium-zinc-magnesium alloy coated AM100/AM125, zinc-aluminium alloy coated AZ150 and galvanised Z450 conform to AS 1397:2021.

Stramit has a comprehensive range of colours as standard. Ask your nearest Stramit location for colour availability.

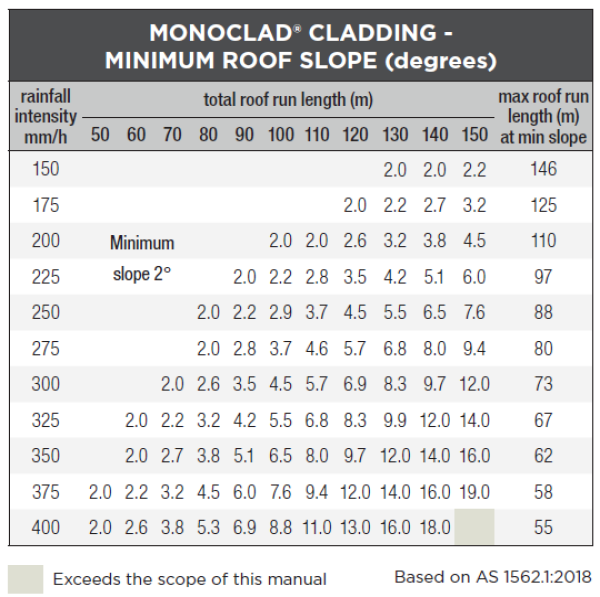

The minimum roof slope for Stramit Monoclad® Roof and Wall Cladding is 2 degrees.

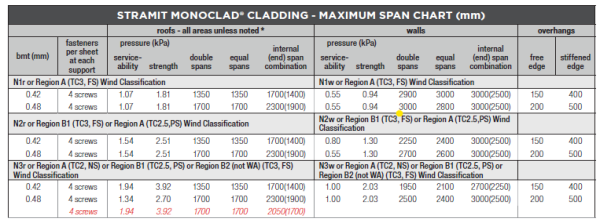

The spans shown below take account of 'normal' foot traffic and wind resistance including local pressure zone effects. Pressures are based on AS 4055:2021 or AS/NZS 1170.2:2021.

Where the two standards differ, the worst case has been taken for each classification. Data should only be used for buildings with dimension limits given in AS 4055:2021, 7m or less in average height, 16m max width and length less than 5 times the width, where both length and width exceed the building height and site is unaffected by land topography. Maximum roof pitch 35°. Refer to AS 4055:2021 for more detail.

*Where roof pitch is less than 10 degrees, use spans given in red italics for roof corners. Internal spans must have both end spans 20% shorter. TC – Terrain Category. FS, PS, NS – Full, partial and no shielding. Internal coefficient +0.2/-0.3.

Values are only valid for use with steel members of 1.5mm or thicker. Where thinner supports are used, fastener capacity must be checked. Refer to Stramit® Top Hat & Battens Product Technical Manual for more information.

For more specific applications Monoclad® cladding must be designed to the pressure and foot traffic limitations indicated.

Roof spans may exceed those shown in this table, provided the wind pressure and foot traffic limits are not exceeded.

Stramit Monoclad® Roof and Wall Cladding can be spring-curved, concave or convex, including curved ridges, provided it is sealed at the apex, and within the recommended limits below.

*At these radii a maximum support spacing of 1200mm applies, and limit state pressure capacities are reduced by 14% for serviceability and 7% for strength. These reductions apply proportionately up to the lowest neutral radius.

All metal roof sheeting is subject to thermal expansion and, where there is a temperature difference between the sheeting and the structure, this needs to be accommodated. The colour of the sheeting will affect the amount of thermal expansion, and whether the sheet is flat or curved will affect its ability to resist without problems. Sheet lengths should be limited to those shown below.

Larger roof run lengths on a single plane support structure can be readily constructed using the MonoLap® Roof Lap Joint System.

Monoclad® Roof and Wall Cladding has excellent water-carrying capacity enabling roof slopes to be as low as 2° for many applications. Roof run lengths are the combined lengths of all roof elements contributing to a single pan drainage path. This can include the roof length upstream of a roof penetration that concentrates flow into other pans.

The table below gives slopes for 100 year return period rainfall intensity.

Stramit’s Roof Slope Guide provides additional information.

Derived from testing, the following tables give the wind load resistance for both serviceability and strength limit states.

Tables are based on testing to AS1562.1:2018 and AS4040 parts 0 and 2. Internal spans must have both end spans 20% shorter.

Values only valid for use with steel support members of 1.5mm or thicker. Where thinner supports are used, fastener capacity must be checked. Refer to Stramit® Top Hat & Battens Product Technical Manual for more information.

Refer to Stramit® Cyclonic Areas Roof and Wall Cladding brochure for information on use in cyclonic regions.

Installation Information

Stramit's cladding can be easily cut, where required, using a power saw with a cold cut saw blade or a power nibbler and, for localised cutting, tin snips. Avoid the use of abrasive discs as these can cause burred edges and coating damage. Please dispose of any off-cuts carefully and thoughtfully.

Stramit Monoclad® Roof and Wall Cladding is readily installed with or without a fibreglass insulation blanket. If practical, lay sheets in the opposite direction to prevailing weather.

Installation of Stramit Monoclad® Roof and Wall Cladding is a straightforward procedure using the following fixing sequence.

- Ensure all purlins are in line and correctly installed and that mesh and blanket (if specified) are in place.

- Position and fix the first sheet ensuring the correct sheet overhangs (minimum 50mm). Ensure that screws are not overtightened.

- Continue to fix subsequent sheets checking that sheet ends at the lower edge are exactly aligned. It is important that the underlap of one sheet does not protrude beyond the overlap of the next – if this is unavoidable, the underlap must be trimmed locally or water ‘drawback’ may occur.

- Measure the overall cover width at top and bottom of the sheets from time to time to avoid ‘fanning’.

- For roof spans exceeding 900mm and wall spans exceeding 1200mm, stitch the sidelaps at midspan.

- Turn up the pans at the upper roof edge, turn down the pan at the lower edge and install flashings.

- Clean up the roof after each days work, removing all screws, cuttings, swarf etc, and leave roof clean and watertight.

The Stramit MonoLap® roof lap joint is a revolutionary system (patent pending) that changes the way long run roof cladding is designed and installed. It provides a multiple sheet option for long length screw fixed roofing projects that eliminates traditional step joints or the need for long on-site rolled sheets, without compromising the integrity of the roofing structure.

Designed specifically for Stramit Monoclad® Cladding, the Stramit MonoLap® roof lap joint system allows the installation of lapped sheets on standard purlin framing, without the need for conventional stepped jointing. The system provides a combination of a strong joint and a weather-resisting seal between lapped sheets.

The system is simply installed by placing onto the bottom sheet with enlarged holes in the ribs. The top, overlapping sheet is then placed over the Stramit MonoLap® units, and screwed through both layers to the support below. The joint connectors and sealing foam are manufactured from high technology materials that provide strength and weather-resistance and preserve the existing roofing warranty.

Stramit MonoLap® roof lap joints can only be used with Stramit Monoclad® Roof Cladding and with the following provisions:

- installed on roofs specifically designed for its use

- all purlins must be in a single plane, i.e. no step down

- purlins must be spaced to allow for sheeting end spans on either side of the joint, and

- translucent sheeting joints must coincide with the decking joint.

For detailed information refer to the Stramit MonoLap® Product Technical Supplement, or download the Stramit MonoLap® Roof Lap Joint System Promotional Flyer.

Stramit MonoLap® lap joints are readily installed on Stramit Monoclad® Roof Cladding. Stramit Monoclad® Roof Cladding sheets are installed in the normal manner, except that:

- Alignment of the sheets on the lower and upper runs must be determined before commencing the laying of sheets on the lower run to ensure the ribs match at the joint.

- Lower run sheets must be placed with 200mm overhang beyond the centre of the support at the joint. Stringline or chalk to show the centre of the support at this position.

- Sheeting is screwed down as per normal practice at all supports except at the joint. Turn up the high ends of the lower sheet in every pan using the Stramit MonoLap® turn-up/down tool.

- Translucent sheeting for a lower run should be fixed before laying decking on an upper run.

When installing the Stramit MonoLap® units:

- Position the Stramit MonoLap® roof lap joint roll with the centre of the hole in the protruding nylon part over the centreline of the support, and the foam further away from the higher end of the lower sheet.

- Connect subsequent rolls by unclipping the nylon unit with no foam on one side, inserting the end of the next roll with only foam through the joining pin, then pushing the pins back into the mating holes until it clicks into place.

- Carefully align the side edges of the higher sheet with the first lower sheet and position with a 150mm overhang. Screw sheeting to all supports except at the joint.

- Drill a 16mm hole at the top of each rib at the string line position at the joint, through both layers of sheet only. Turn down the upper sheet pans at the joint using the MonoLap® turn-up/down tool.

- Position a MonoLap® cap over the 16mm hole. Screw through using a No 12 -14x68mm Tek screw through both layers of sheeting and into the support below.

For full installation details refer to the MonoLap® Installation Supplement and the MonoSky® Installation Supplement.

For use in conjunction with the Stramit MonoLap® Roof Lap Joint System, the Stramit MonoSky® joint is only suitable for the fibreglass over fibreglass joint and the edge joint of the fibreglass over the Stramit Monoclad® sheeting.

Fibreglass sheet overlaps should be a minimum of 350mm as per the Stramit MonoLap® Product Installation Supplement. For full installation instructions refer to the Stramit MonoSky® Joint System Installation Supplement.

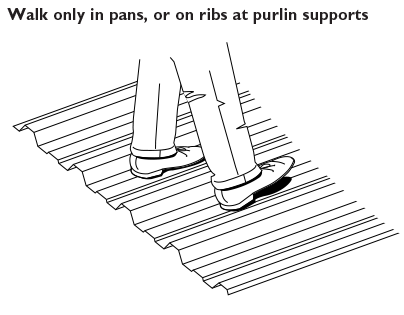

As with all roofing products, we recommend extra caution be taken when walking on the roof. When walking on Stramit Monoclad® Roof and Wall Cladding always wear flat rubber soled shoes and place feet only in the pans, taking care to avoid the last pan or two near edges of the metal roof area. Walk only in pans, or on ribs at purlin supports.

Below are some handy hints and tips to achieve maximum life from your COLORBOND® and ZINCALUME® finished products.

- In areas of little rainfall, products should be cleaned regularly.

- Brick cleaning acid should not come into contact with steel fascia, gutter, or roofing and walling.

- Never immerse these products in sand, soil or concrete.

- Do not use touch up spray can paint on COLORBOND® steel.

- Remove metal debris from cutting and/or drilling to avoid swarf damage.

- Prior to installation, keep bundled material dry.

- Prepainted metal roofing components should be stored in the shade as the protective plastic film will become difficult to remove if it is exposed to direct sunlight.

- Make sure materials made of different metal, such as copper and lead, do not make contact with these products, and water does not run from one to the other.

- Roofing and guttering should be free draining and free from dirt and leaves.